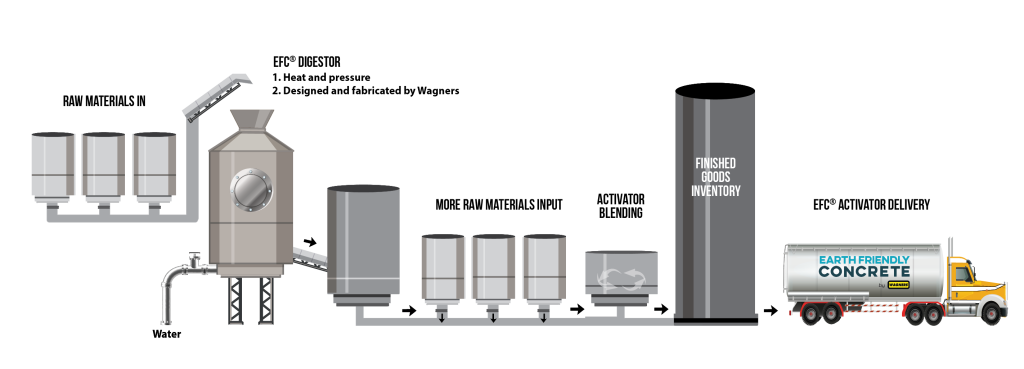

Wagners EFC has developed a scalable business model to distribute EFC activator. The manufacturing process requires much lower capital investment when compared with competing low carbon technologies, it is a relatively seamless plug into existing concrete production plants.

Chemical manufactured and distributed to concrete producers. EFC Activator replaces some of the water content at the point of concrete production. It is a very simple addition to a standard concrete plant.

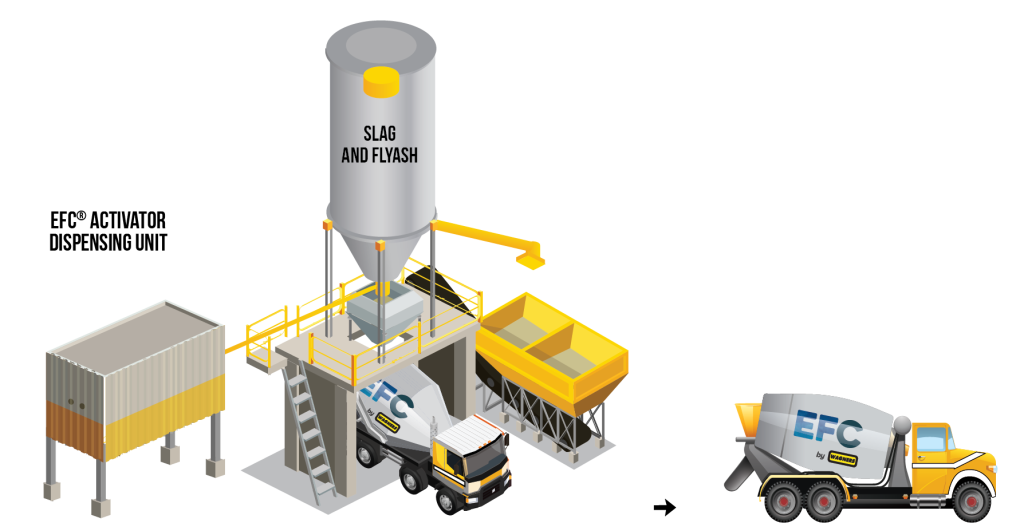

EFC Activator dispensing units store and dose the activator at each concrete plant. This is a very simple and cheap piece of equipment. Wagners EFC will install these under an operating lease model.

Technical consulting for concrete mix design & development and specialty application support. This allows clients to rapidly deploy EFC technology so they can deliver Earth Friendly Concrete across applications and concrete products.

We deliver our EFC Activator solution along with our EFC Act Mixture to your local concrete batch plant or precaster.

The concrete produces uses it natural raw materials… except concrete

They deliver Earth Friendly Concrete to your project.

Established in 1989, Wagners is an ASX-listed company operating globally. Wagners are a producer of cement, concrete, aggregates, new generation composite products and are world leaders in the development of new technology to reduce the impact of heavy construction materials on the environment. The company also provides transport services, precast concrete and reinforcing steel.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |